Categories

- - Deep Well Submersible Pump

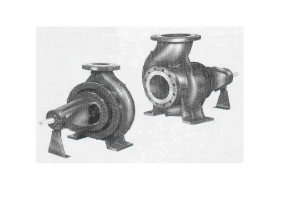

- - End Suction cenfrigual Pump

- - End Suction Close cenfrigual Coupled Pump

- - Fire Pump

- - Gear Pump

- - Horizontal Multistage Pump

- - Horizontal Split Casing Pump

- - Motors

- - Pressure Booster Pump

- - Submersible Pump

- - Valves & others

- - Vertical in-line Pump

- - Vertical Multistage Pump

- - Vertical submersible Pump

- - Vertical Turbine Pump

Author Archives: safeway

Applications:

High precision positive displacement internal gear pump to match the most demanding application in boilers, burners, hydraulic, fuel pressuring and injection. This pump is ideally suitable for handling liquid like LDO, FO, LSHS and HSD. It can be used as booster pump for diesel locomotive, pump for force deed lubrication, in oil filtration system, oil pumping and heating systems and in machine tool units.

High precision positive displacement internal gear pump to match the most demanding application in boilers, burners, hydraulic, fuel pressuring and injection. This pump is ideally suitable for handling liquid like LDO, FO, LSHS and HSD. It can be used as booster pump for diesel locomotive, pump for force deed lubrication, in oil filtration system, oil pumping and heating systems and in machine tool units.

Applications:

It is suitable for transfer of corrosive chemical & viscous liquids..

It is suitable for transfer of corrosive chemical & viscous liquids..

Advantages:

- Complete SS316 investment casting

- Nitrided gears and shafts for longer life

- Teflon coated bush for smooth performance

- Zero leakage PTFE type Z – Pac sealant in gland

- Optimum internal clearance for accurate capacity and lower power consumption

Applications:

It is suitable for pumping and transfer of all kind of viscous liquids and petroleum products.

It is suitable for pumping and transfer of all kind of viscous liquids and petroleum products.

Technical Data:

- Flange Connection

- Double helical herring bone gears

- Inbuilt pressure relief valve

- Self priming pump with 5m suction lift

- Optional mechanical seal

- Self or independent fabrication

- Optional high temperature version

- Maximum capacity: 125 m³/h

- Maximum temperature: 120º C

- Maximum pressure: 12 kg/cm²

- Maximum viscosity: 5000 CST

General Characteristics

- Single or multistage pumps

- Horizontal or vertical mounting

- Total head of 30m ~ 250m

- Material of construction: Cast Iron or Stainless Steel

- Sealing with mechanical seal

- Single stage electric motor (230V / 50 Hz) up to 2.4kw

- Three phase electric motor (400V/440V – 50 Hz /60 Hz)

- Pressure vessel size upon application

- Common collection suction – discharge or calculated diameter

- Cast Iron or Stainless Steel Collection

Applications Technical Data

- High rise buildings - Liquid Temperature: 0 ~ 70º C

- Offices - Ambient Temperature: Max. 40º C

- Schools

- Irrigation systems

- Industrial production

- Municipal supply systems

General

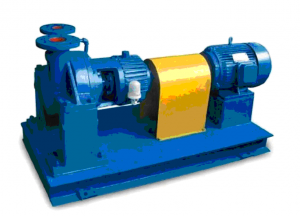

Pump Type SJ is a new model Pulp Pump, designed on the basis of pulp’s feeding through liquid, solid and gas. Developed by advance technique, suitable for the severe condition of the pulp making and paper making trade. It has not only wide performance range and small intervals between parameters, but also takes. So it can save energy and increase the capacity of the pump, which delay its using life.

Performance Range

Capacity: 20 ~ 1600 m³/h

Head: 8 ~ 50m

Pulp Density: ≤5%

Working Temperature: ≤100º C

Applications:

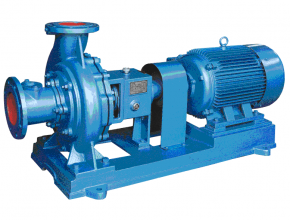

- For clean or turbid liquids, free from large solids

- For pumping water, petrol, benzene, oil, brine, alkaline solutions and mild acids

- For circulation, irrigation and drainage purposes

- For water supply and booster stations

- For industrial and agricultural applications and in public services

Operating Data:

- Capacity: up to 570 m³/h

- Head: up to 160m

- Working Temperature: up to 140º C

- Working Pressure: 16 bar

Applications:

- For clean or turbid liquids, free from large solids

- For pumping water, petrol, benzene, oil, brine, alkaline solutions and mild acids

- For circulation, irrigation and drainage purposes

- For water supply and booster stations

- For industrial and agricultural applications and in public services

Operating Data:

- Capacity: up to 150 L/sec

- Total Head: up to 150m

- Working Temperature: up to 100º C

- Working Pressure: 10 bar (H: 16 bar)

Materials:

- Pump Casing: Cast Iron, Bronze or Stainless Steel

- Impeller: Cast Iron, Bronze or Stainless Steel

- Shaft: AISI 304 - 316

- Sealing with Mechanical seal or Packing gland

Structure Features

- MS/MSS series of pump is ingle stage centrifugal pump and features axial suction and radial discharge.

- Compact structure, the pump is directly connected with the motor, coaxial installation.

- Convenient installation, screw thread water inlet and outlet.

- Light weight, thin plate pressing structure for main parts and components.

- A little corrosion resistance, material of wet part is AISI 304 or AISI 316 stainless steel.

- MS/MSS series of pump is ingle stage centrifugal pump and features axial suction and radial discharge.

- Compact structure, the pump is directly connected with the motor, coaxial installation.

- Convenient installation, screw thread water inlet and outlet.

- Light weight, thin plate pressing structure for main parts and components.

- A little corrosion resistance, material of wet part is AISI 304 or AISI 316 stainless steel.

Application

- Pressurization and pumping of industrial and civilian clean water or other liquids.

- Water treatment.

- Water circulating system.

- Agricultural irrigation.

- Other fields.

Operation Condition

- Liquid temperature: -10°C ~ +85°C.

- Ambient temperature: up to +40°C.

- Altitude: up to 1000m.

- Max. pressure of the system is 8 bars.

Motor

- TEFC motor, 2 pole.

- Protection class: IP55

- Insulation class: F

- Standard voltage: 50Hz 1 x 230V

3 x 415V

Applications

- Drinking water supply

- Pressure Booster of domestic system

- Water treatment

- Fountains

- Emptying tank and pools

- Pumping clean water and moderately aggressive industrial liquids

- Cooling tower

- Drinking water supply

- Pressure Booster of domestic system

- Water treatment

- Fountains

- Emptying tank and pools

- Pumping clean water and moderately aggressive industrial liquids

- Cooling tower

Performance Limits

- Max. working pressure: 10 bar

- Max. liquid temperature: -15º C to 110º C

Motor

- TEFC motor, 2 pole.

- Protection class: IP55

- Insulation class: F

- Standard voltage: 380 – 415V (50Hz or 60Hz)

Materials

- Pump casing, impellers, diffusers and shaft: AISI 304 or 316L stainless steel

- Support, motor frame: Aluminum

- Standard mechanical seal: NBR / Ceramic / Carbon